The construction industry is highly dependent on a smooth and efficient supply chain to ensure timely project completion. However, supply chain disruptions range from material shortages and fluctuating costs to logistical and regulatory issues. It can also severely impact productivity and profitability. Traditional supply chain management methods often fall short of addressing these complexities, leading to project delays, budget overruns, and resource misallocation. This is where the construction ERP solution for the supply chain comes into play.

ERP software helps integrate various business processes into a centralized system, It also provides real-time data, automation, and enhanced collaboration. Leveraging ERP software can significantly reduce Construction supply chain disruptions and maintain seamless operations.

Read this blog to explore how ERP software tackles key supply chain issues in construction and manages cost efficiency, cost savings, and project success.

Table of Contents:

- Common Challenges in Construction

- How ERP Software Eliminates Supply Chain Disruptions?

- Conclusion

- FAQs

Common Supply Chain Challenges in Construction

01. Material Shortages and Procurement Delays

Construction projects involve different categories of items in the supply chain. However, procurement inefficiencies, supplier issues, and market fluctuations often cause delays.

02. Lack of Real-Time Visibility

Traditional supply chain management in construction lacks real-time monitoring, making tracking inventory, shipments, and resource allocation difficult. This lack of visibility leads to mismanagement and project delays.

03. Vendor Management Complexities

Construction companies rely on multiple vendors for materials, equipment, and services. Managing multiple projects and suppliers simultaneously without a streamlined system leads to coordination failures and increased costs.

04. Logistics and Transportation Issues

Timely material delivery is crucial for uninterrupted construction. However, transportation delays due to inefficient scheduling, weather conditions, or traffic congestion can impact project timelines.

05. Cost Fluctuations and Budget Constraints

Market price volatility and fluctuating supply costs make budgeting challenging. Without a centralized cost-tracking system, construction firms struggle to maintain financial control.

06. Compliance and Regulatory Hurdles

Construction companies need to comply with various safety and environmental regulations. Non-compliance can lead to project shutdowns, penalties, and reputational damage.

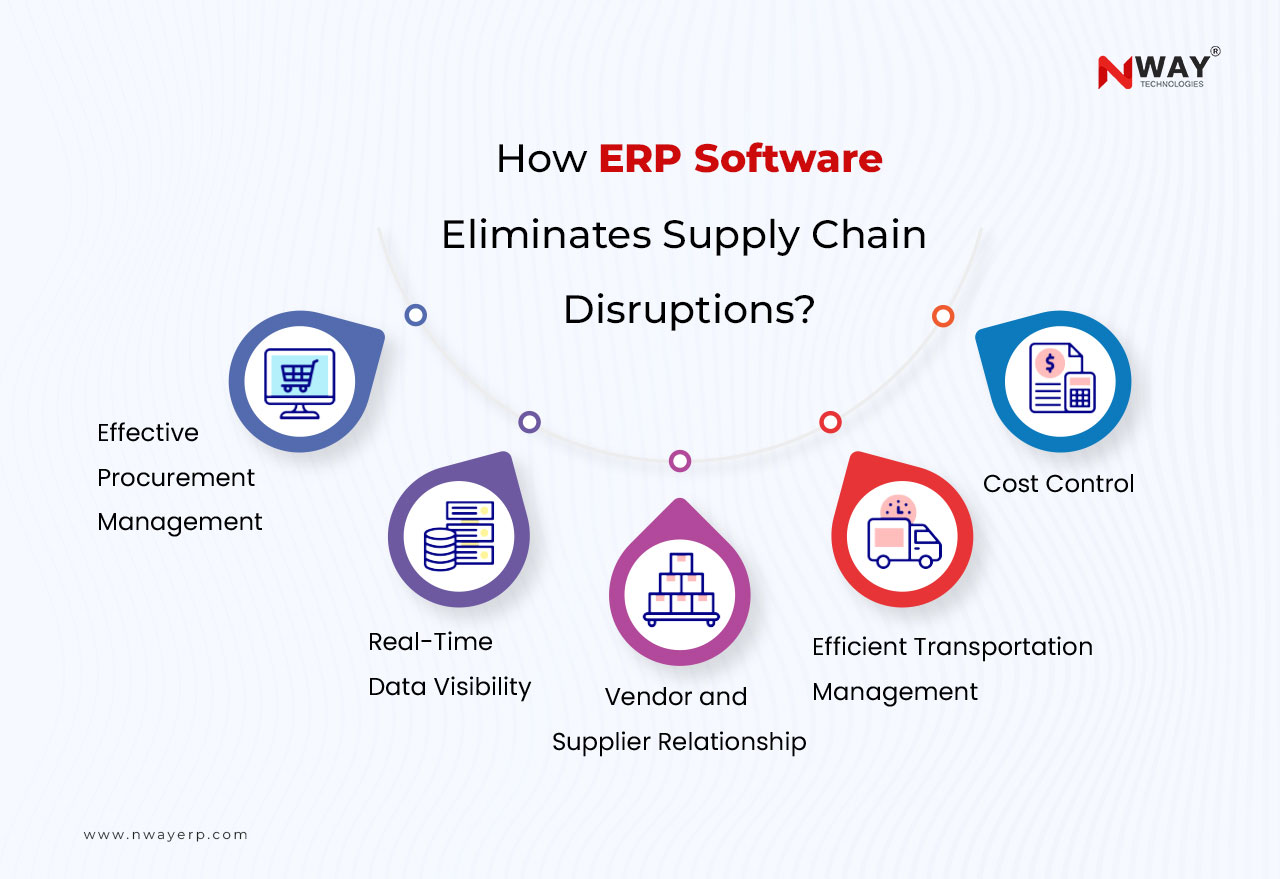

How ERP Software Eliminates Supply Chain Disruptions?

01. Effective Procurement and Inventory Managementt

ERP software streamlines the procurement process, creating purchase orders, tracking real-time inventory in construction, and forecasting material requirements. This also helps in preventing stockouts, over-purchasing, and managing a steady supply of essential materials.

Key Benefits:

Effective generation of supplier communication for faster order processing.

Real-time stock-level monitoring to avoid shortages.

Demand forecasting to plan procurement efficiently.

02. Real-Time Data and Visibility

ERP provides real-time insights into the construction supply chain, allowing project managers to track shipments, monitor supplier performance, and make future predictions. This transparency activates proactive decision-making, reducing disruptions.

Key Benefits:

Centralized dashboard for end-to-end supply chain visibility.

Prompt notifications for updates and inventory changes.

Data-driven decision-making for improved planning.

Read our latest blog on Real-Time Project Tracking and Reporting with ERP for Road Construction and learn more about real-time project management, data, and visibility.

03. Vendor and Supplier Relationship Management

An ERP system helps construction companies manage supplier contracts, assess vendor performance, and ensure compliance with agreed terms and conditions. This improves vendor performance and strengthens supplier relationships.

Key Benefits:

Vendor rating and performance tracking.

Effective contract management and compliance tracking.

Supplier collaboration for better coordination and timely deliveries.

04. Efficient Logistics and Transportation Management

ERP software helps optimize transportation routes and schedule deliveries.

Key Benefits:

Route optimization for reduced transportation costs.

Real-time tracking of material shipments.

Communication with third-party logistics providers for streamlined delivery.

05. Cost Control and Budget Optimization

ERP software helps construction companies track expenses, manage purchase orders, and analyze cost trends. This also helps ensure that material procurement aligns with budget constraints, preventing cost overruns.

Key Benefits:

Real-time expense tracking for financial control.

Cost comparison and vendor selection tools.

Automated financial reporting for improved budget management.

06. Regulatory Compliance and Risk Management

ERP systems help construction companies adhere to safety, labor, and environmental regulations by maintaining compliance records and managing documentation processes.

Key Benefits:

Centralized compliance documentation for easy audits.

Automated alerts for regulatory compliance and requirements.

Risk assessment tools for proactive issue resolution.

Take control of your construction supply chain with powerful ERP software. Don’t let disruptions slow down your projects.

Conclusion

Construction supply chain management in various disruptions that can significantly impact project timelines, budgets, and overall efficiency. ERP software provides effective solutions to these challenges by streamlining procurement, enhancing visibility, improving vendor relationships, optimizing logistics, controlling costs, and ensuring regulatory compliance

By improving a robust construction ERP, companies can mitigate supply chain risks, enhance operational efficiency, and complete projects on time within budget. Investing in ERP technology is no longer a luxury but a necessity for construction companies aiming for long-term success in an increasingly competitive industry. So, how are you managing the supply chain in construction operations? Do you think ERP software can enhance your operations? If so, we can help you. Request a demo now, and one of our experts will get back to explain your industry challenges with an efficient solution.