In the fast-paced construction world, various operations like procurement, inventory, HR & payroll, finance, and more exist. All these need to be managed effectively daily. Effective inventory management ensures projects are completed on time and within budget. Materials, tools, and equipment are the lifeblood of any construction project, and mismanagement can lead to delays, cost overruns, and operational inefficiencies. With the increasing advent of digital transformation construction inventory management with ERP software has emerged as one of the most powerful tools.

Explore this blog to learn more about inventory management systems and how construction ERP software can streamline operations in the construction industry.

What is Inventory Management in Construction?

Inventory management in construction is a process of ordering, storing, using, and tracking stock, including raw materials, finished goods, and other required items of construction. Some of its essential elements are cement, steel, machinery, and consumables. It ensures stock levels and avoids shortages or excesses.

What is an Inventory Management Software?

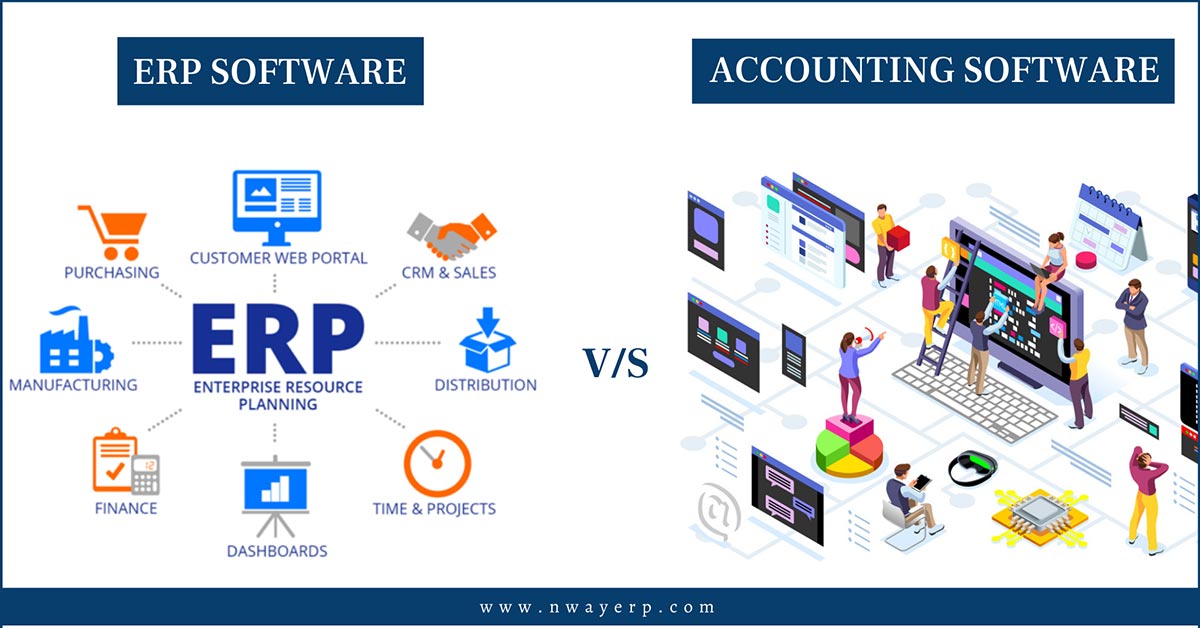

Inventory management software tracks and manages inventory levels, orders, sales, and deliveries. In the construction industry, it helps monitor inventory materials and equipment flow from suppliers to construction sites. Construction inventory management with ERP software provides real-time visibility, effective workflows, and analytical insights, making it indispensable for efficient operations.

Challenges Faced by Construction Companies in Inventory Management

Inaccurate Stock Levels

Construction projects often span multiple locations, making it difficult to provide accurate stock records.

Material Wastage

Over-ordering or inefficient storage of materials leads to insignificant use of resources resulting in increased costs.

Lack of Real-Time Tracking

Without real-time tracking, identifying the exact location and status of materials becomes cumbersome.

Inefficient Procurement Processes

Inefficient procurement processes can affect other construction operations and activities leading to missed deadlines.

Manual Errors

Using and managing manual methods like papers, documents, and spreadsheets for inventory management often leads to chaos, miscommunication, and data inconsistency.

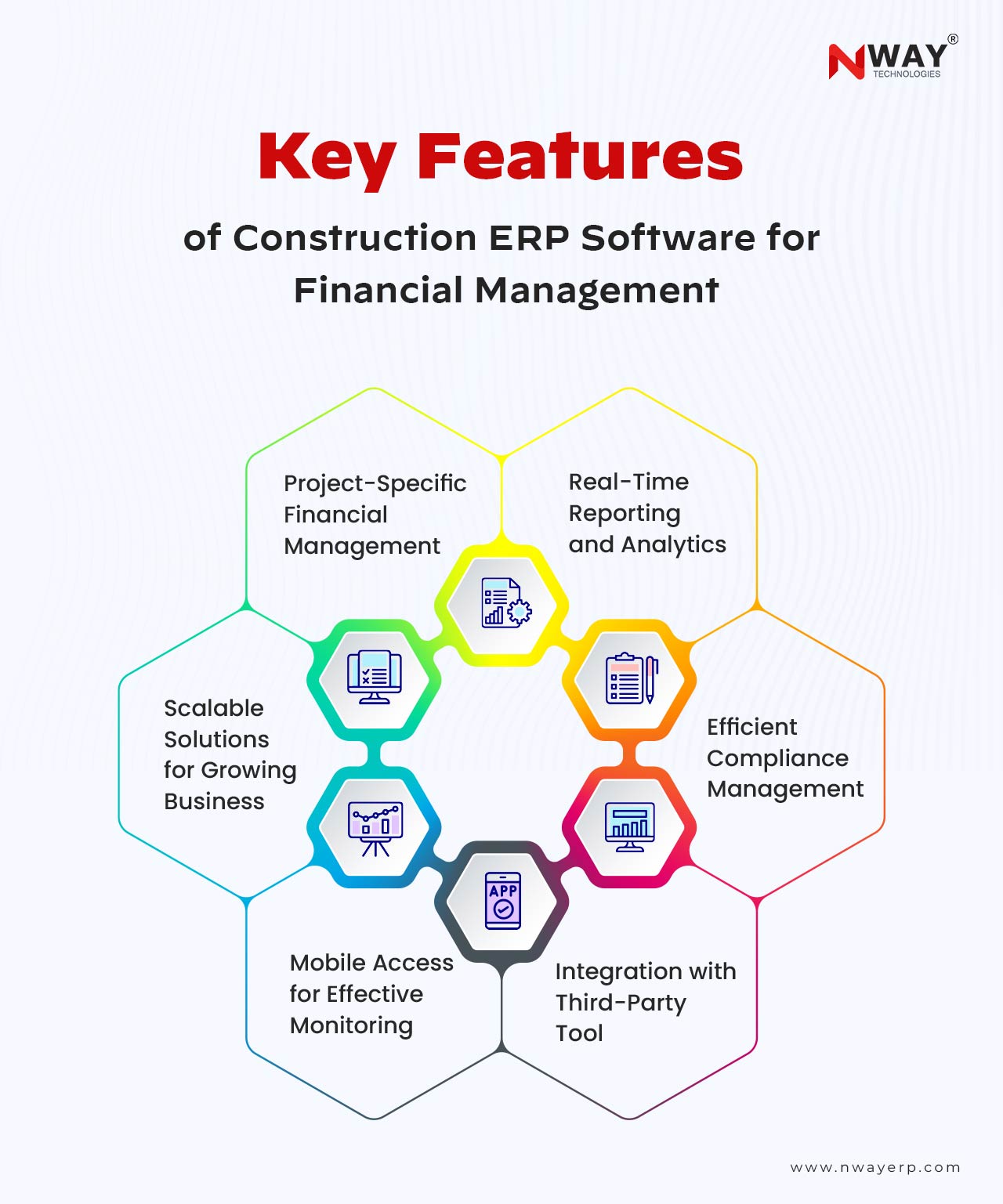

Features of Construction Inventory Management Software

Inventory Tracking

Real-time tracking of inventory across multiple locations to ensure optimal stock levels.

Effective Reordering

Set thresholds for effective reordering of materials to prevent shortages and efficient management.

Barcode and RFID Integration

Construction inventory management software provides advanced technologies for accurate inventory scanning and management.

Forecasting Tools

Leveraging historical data and analytics to predict future inventory levels and needs.

Integration Capabilities

Seamlessly integrate with procurement, accounting, and project management modules within an ERP system.

Customizable Dashboards

Access user-friendly dashboards tailored to specific businesses for quick decision-making.

Alerts & Notifications

Timely notification and intimations for low stock levels, shipment progress, delays, and overstocking.

Benefits of Using Inventory Management Software

Real-Time Tracking

Construction inventory management with a specific ERP system can provide real-time visibility of stock levels, helping companies avoid shortages or surpluses.

Enhanced Efficiency

Efficient workflows streamline ordering, tracking, and replenishing materials, saving time and reducing manual effort.

Reduced Wastage

By tracking inventory levels effectively, construction managers can reduce wastage and manage resources efficiently.

Cost Savings

Efficient inventory management prevents over-purchasing and reduces storage inefficiencies along with controlling costs.

Improved Decision Making

Analytics and reporting tools provide actionable insights, enabling better planning and forecasting.

Centralized Data Access

A unified platform ensures that all stakeholders can access up-to-date information, fostering better collaboration.

Why Choose NWAY for Inventory Management?

Comprehensive Solutions

NWAY offers an all-in-one construction ERP software that seamlessly integrates inventory management with other critical construction processes like procurement, accounting, and project management.

Real-Time Visibility

It offers real-time tracking of inventory across multiple sites, managing effective stock levels and reducing materials wastage.

Customizable Features

Tailor the software to meet your specific needs with customizable dashboards and modules.

User-Friendly Interface

It involves features that are easy for users to adopt and operate efficiently.

Advanced Analytics

Leverage powerful reporting capabilities and forecasting tools to gain actionable insights and make informed decisions.

Dedicated Support

It provides exceptional customer support to assist with implementation and ongoing use, ensuring a smooth transition and maximum ROI.

Proven Track Record

Trusted by leading construction companies, it has a proven track record of delivering robust ERP solutions tailored to industry challenges.

Conclusion

Inventory management is a critical component of construction project success, and the adoption of inventory management software within a robust ERP system can address many challenges faced by the industry. By providing real-time insights, reducing wastage, and optimizing resource allocation, Construction inventory management software helps focus on achieving operational excellence. So choose a trusted partner like NWAY to further enhance these benefits, making it easier to navigate the complexities of inventory management. Contact us now and discuss this with a team of experts.